A BCM is one of the most important controllers in a vehicle, as this module

manages a wide variety of other functional modules such as windshield wipers,

lights, door locks, windows, switches, etc. Recent trends in the automotive

industry show increasingly more complex features for vehicle intelligence,

electric vehicle internet connection and autonomous driving. The addition

of separate electronic modules boosts both the cost and the fault rate of

electronic parts and components, making wiring much more complicated.

Driven by new-generation E/E architecture, BCM components are integrating

more control nodes and moving toward body-domain controllers.

Communications With All ECUs and Sensors, Control Over All Actuators

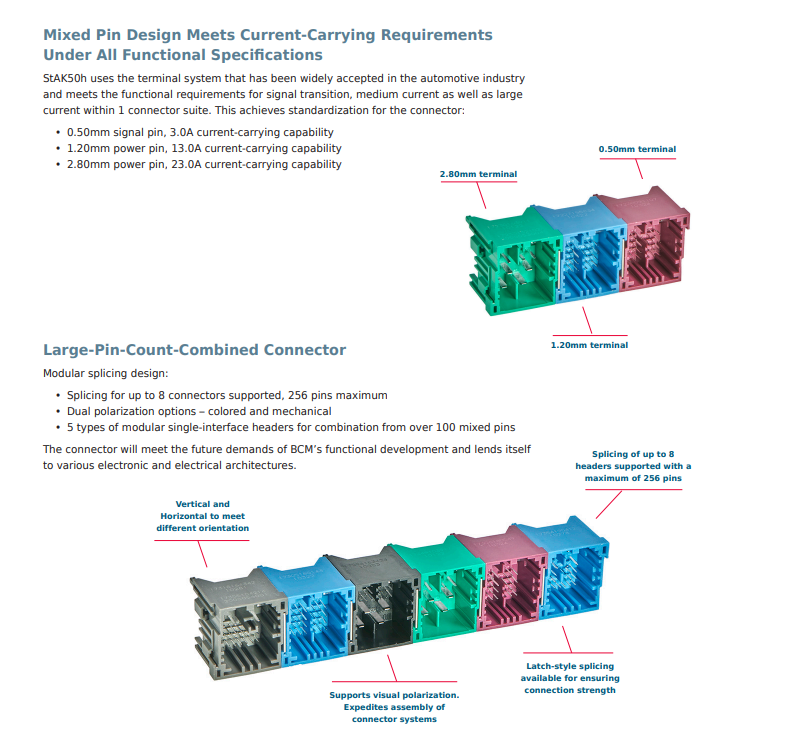

A typical BCM connector normally has the following functional specifications:

• Sensor signal, CAN/LIN, electric current less than 100.0mA, 50 to 70 pins

• Stepping motor, lighting and antenna, electric current less than 3.0A, 30 to 50 pins

• Power supply, ground and electric current, 10.0 to 20.0A, 15 to 25 pins

The BCM connector, therefore, requires mixed pins that provide different current-carrying capabilities.

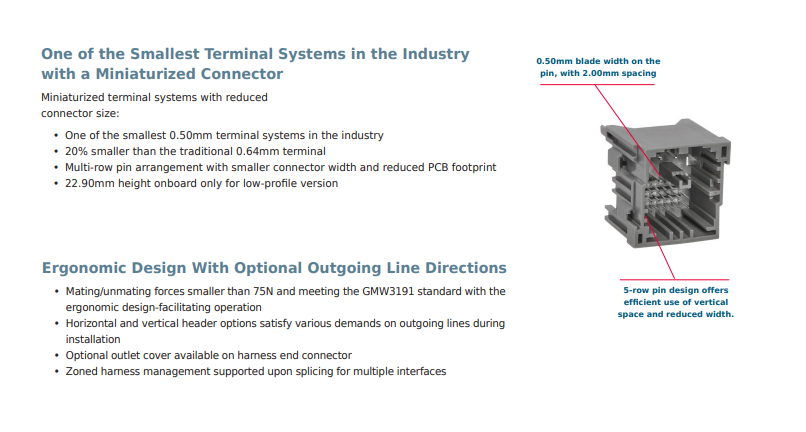

Restricted BCM-Mounting Space Trends Toward Module Miniaturization

The BCM is often mounted beneath the dashboard or around a pillar, where a wide variety of elements are

accommodated and the space is narrow. As a result, the connector needs to have the following features:

• Small footprint

• Height no more than 30.00mm; width as narrow as possible

Simplified Harness Wiring Facilitates Installation Operation

The mounting position and direction for the BCM vary by specific vehicle model. The following requirements

are necessary to simplify the harness arrangement:

• IP42 protection, requirement that the connector not be mounted on the top of the module

• Zoned management needed as the BCM connects to the main harnesses

• Ease of installation and mating/unmating of the connector

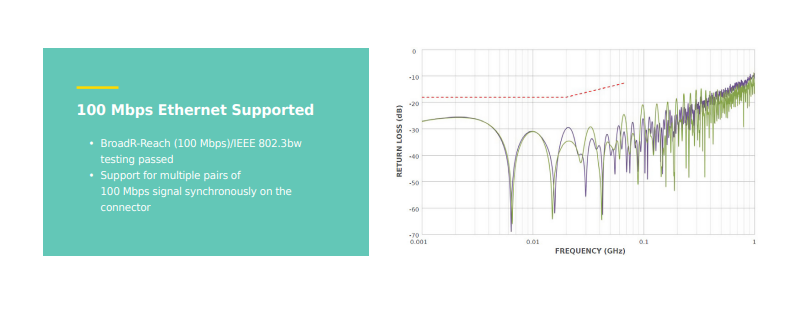

Support for Ethernet Scalability

The Ethernet provides these advantages as a new-generation communication protocol:

• Higher bandwidth

• Lower cost, as the unshielded single-pair twisted wire for BroadR-Reach doesn’t need aluminum foil and

insulating compound layers

• Suitability for the development of new-generation electronic and electrical architecture

• Note: The BCM may require a megabit Ethernet communication